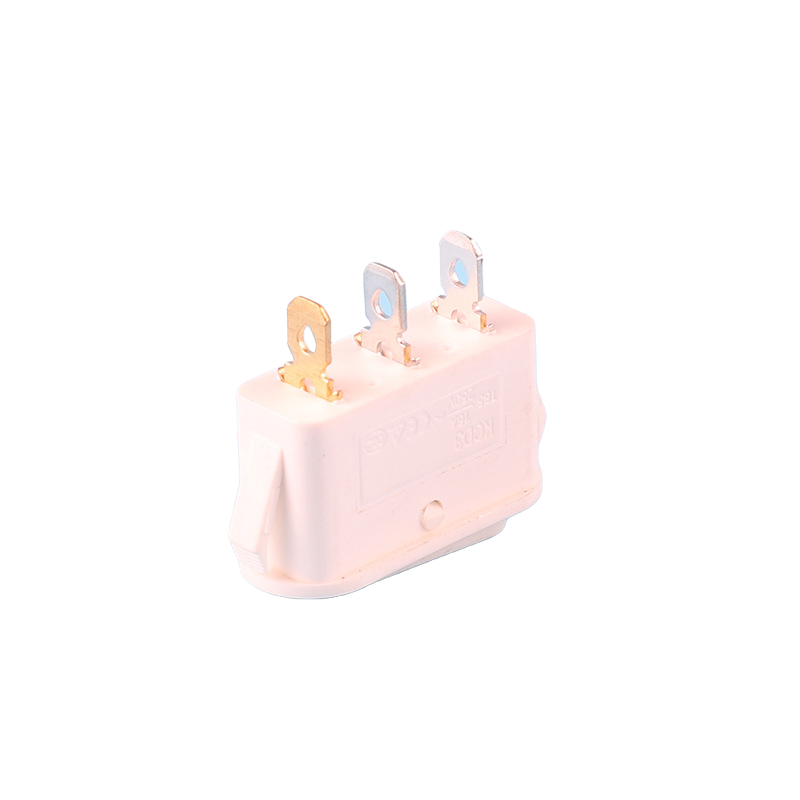

China Factory Rocker Switch KCD3 oval shape rocker switch 3 pins ON OFF Lighted Rocker Switch With LED fo home appliance

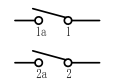

Circuit:

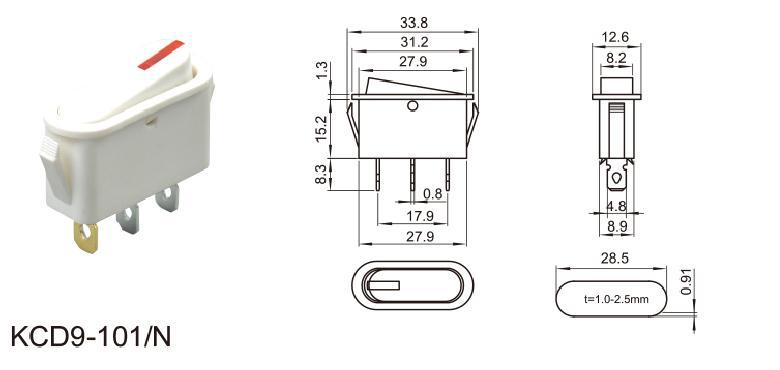

Drawing

Type of switch

SPST: 1 moving contact and 1 stationary contact. only 1 channel

SPDT: 1 moving contact and 2 static contacts, (the static contacts on both sides can be connected respectively)

Double pole single throw: 2 moving and 2 stationary contacts, with 2 channels

Double pole double throw: 2 moving contacts and 4 static contacts, there are 4 channels (2 static contacts on both sides can be connected respectively)

Introducing Our High Quality Rocker Switches: Rugged, Reliable, Durable

Application

Rocker Switch for Marine Equipment

Product Description:

Engineered to withstand harsh marine environments, the rocker switch for marine equipment is rated up to 15A, 24V DC. It features water-resistant and corrosion-resistant materials, ensuring long-term reliability and performance. Available in various colors and illumination options, it suits specific marine applications.

Application:

Used to control navigation lights, bilge pumps, and other critical systems, this switch ensures reliable operation in all weather conditions. Its water-resistant design prevents failure due to saltwater and humidity exposure. Custom illumination enhances visibility and usability during night operations. Marine equipment manufacturers can rely on this switch to provide robust and user-friendly controls, ensuring safety and convenience for boat owners.

Rocker Switch for Industrial Machinery

Product Description:

The rocker switch for industrial machinery is a heavy-duty control solution designed to handle high-power loads. Rated up to 20A, 250V AC, it is built with durable materials to withstand harsh industrial environments. Customizable in terms of size, color, and illumination, it meets specific industrial requirements.

Application:

Ideal for machinery control panels, this switch provides reliable on/off control for equipment like conveyor belts, power tools, and industrial ovens. Its robust construction ensures durability in demanding conditions, including exposure to dust, moisture, and vibrations. Customizable features enhance usability and integration into various machinery designs, improving operator safety and efficiency.